Safety valves must be installed with careful attention to several key considerations to ensure proper operation and safety. First, the safety valve should be mounted in an upright position and as close as possible to the equipment or piping it is protecting. If direct access is not feasible, the total pressure loss between the protected equipment and the inlet of the safety valve must not exceed 3% of the set pressure. This helps maintain the valve’s effectiveness under operating conditions.

The inlet piping of the safety valve should include a long-radius elbow to minimize flow resistance and turbulence, ensuring smooth fluid passage into the valve. Additionally, an inspection platform should be provided for easy access during maintenance. For heavier safety valves, it’s important to plan for lifting and disassembly, and in some cases, a crane or boom may be necessary to facilitate this process safely.

When designing the outlet piping, backpressure must be carefully controlled. For standard spring-loaded safety valves, the backpressure should not exceed 10% of the set pressure. Excessive backpressure can affect the valve’s ability to open properly and release excess pressure when needed.

If the safety valve discharges into a closed system, the outlet pipe should be directed to the top of a 45-degree sloped main discharge line. This prevents condensate from entering branch lines, which could increase backpressure and reduce the valve’s performance. When discharging into a venting line or a torch system that contains condensate or condensable vapors, the safety valve outlet must be positioned above the main line. If this is not possible, adequate drainage measures should be implemented to prevent liquid accumulation.

In cases where shut-off valves are installed on both the inlet and outlet of the safety valve, a single-gate valve should be used, and it must be sealed to prevent accidental operation. The valve stem should be installed horizontally to avoid the risk of the valve disc falling due to corrosion or loosening of the connecting pin. If a bypass valve is installed, it should also be sealed off to prevent unintended flow.

Proper installation and maintenance of safety valves are essential for the safe and efficient operation of pressure systems. Following these guidelines ensures that the safety valve functions correctly under all conditions, providing reliable protection against overpressure scenarios.

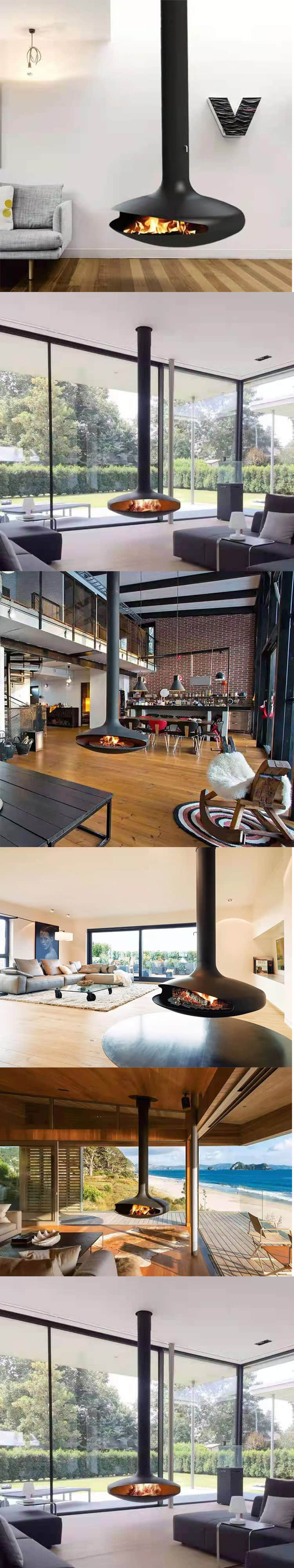

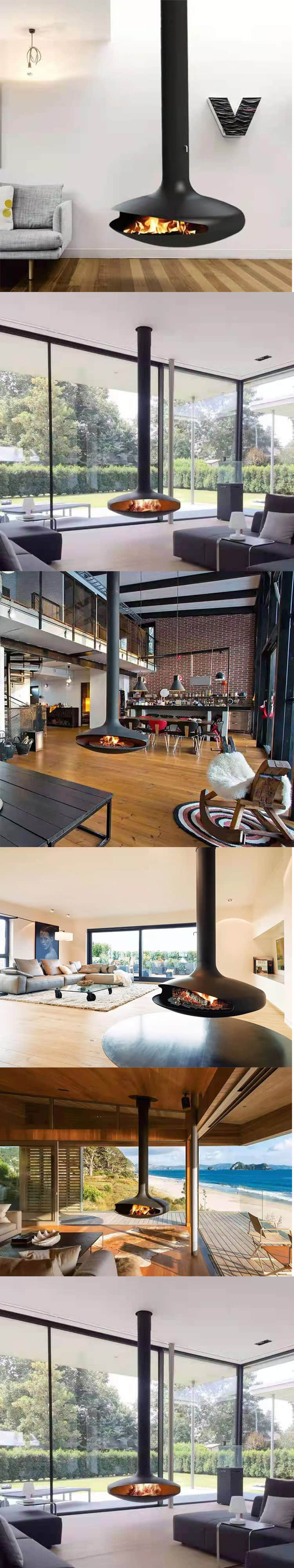

Fire Pit

The fusion of traditional technology and modern aesthetics behind each product is a deep exploration of the material and structure. With "steel" as the medium, the pure manual process journey is opened to convey the Fireplace culture and design ideas to the whole world.From the profound interpretation of contemporary industrial design, strict selection of each raw material, strict control of each process, so that made in China gives new meaning to the fireplace with traditional handwork and modern aesthetics, paying tribute to consumers.Select strong, fire-resistant high carbon steel surface imported heat - resistant paint. Skillfully use modern technology and traditional manual combination to provide high quality products.The use of high carbon steel, molten metal, heat-resistant paint and the minimalist design in line with the current international trend make it a timeless work of art. Made in China makes Mevera fireplace more trusted by people.

|

Name

|

Hanging steel brazier firepit

|

|

Material

|

Corten steel

|

|

Cooking plate Size

|

Diameter 800mm

|

|

Weight

|

65KG

|

|

Packing

|

wooden box packing

|

Packing

Packing will by wooden box.

Ethanol Fire Pit,Bio Ethanol Fire Pit,Alcohol Fire Pit,Biofuel Fire Pit

Henan Jinbailai Industrial Co.,Ltd , https://www.gardensteelarts.com